HISTORIA

Trabajamos con el objetivo de proteger a las personas que usan prendas confeccionadas con nuestros tejidos.

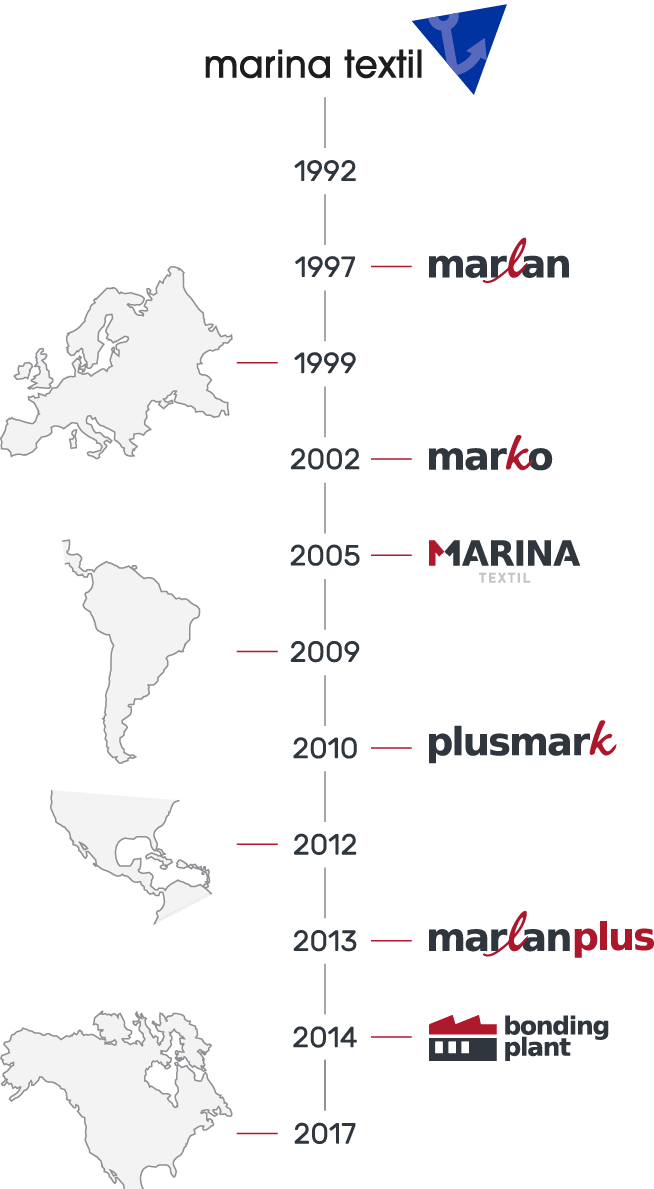

In 1992, Joan proposed that I join a business project in which we would design, manufacture, and sell fashion fabrics. This is how Marina Textil was born. We began our journey with a few looms, working for other local companies and offering our weaving services. In 1996, we launched our first fashion collection for men’s shirting.

In that same year, Marina Textil diversified its focus and began exploring the field of fire-resistant fabrics, also known as flame-retardant fabrics. One of our first launches was MARLAN, a flame-resistant fabric designed to protect against molten metal splashes. This product marked the beginning of our specialization in flame-retardant fabrics.

By 2007, 85% of our production was already focused on flame-retardant fabrics. This evolution not only reflected our adaptability to the market but also completely redesigned our business model and corporate strategy. Constant evolution has become a fundamental value at Marina Textil, as evidenced by the growth of our industrial capabilities, including the incorporation of a lamination plant and the systematic increase of our loom capacity.

Recently, Marina Textil has entered new sectors where flame-retardant fabrics are also used, such as fire protection, extreme temperatures, and racing drivers’ protective gear, through its subsidiaries Texfire and Marina Racewear.

The company’s evolution has led us to implement in-house laboratories focused on research and quality control. These laboratories allow us to test the resistance, durability, and flame-retardant properties of all fibers available on the market, as well as analyze all the fabrics we manufacture, ensuring quality compliance for each batch delivered to more than 70 countries worldwide.

With a constant focus on research and development, and a firm commitment to quality, rigor, and honesty in our relationships with customers and suppliers, Marina Textil remains dedicated to its mission of protecting people through the manufacture of technical fabrics with innovative fibers. The R&D team works in collaboration with universities and research centers to stay abreast of technological and material innovations, continuously improving and innovating our fabrics.

In line with our vision of sustainability, in 2020, we implemented a project that spans from the selection of eco-friendly raw materials to efficient and responsible production processes. We are committed to reducing our carbon footprint and promoting sustainable practices in all our operations and processes, ensuring a greener and more responsible future for the textile industry.

Today, at Marina Textil, we operate with a team of over 90 people, committed and passionate about their work. We are proud of our growth and the trust our customers place in our team, being recognized for our reliability and business philosophy. Thanks to our customers’ trust, we continue to work with the same enthusiasm and commitment as in our early days, ensuring the protection of those who wear garments made from our fabrics.

Thank you for your trust, we will continue to work as we have until now.

Raimon

Director Marina Textil

NUESTROS VALORES

FIABILIDAD

Compromiso total con el cumplimiento en el servicio y los parámetros técnicos del producto.

CRECIMIENTO

Diseñar y ejecutar estrategias pensando en un futuro sostenible y positivo para la compañía.

SOLIDARIDAD

Ayudar activamente con recursos económicos, a personas más necesitadas.

HONESTIDAD

Buscar a través del trabajo el

crecimiento personal y profesional de todo el equipo.

Fabricamos todos los tejidos en las instalaciones situadas en Barberá del Vallès. Allí se encuentra el parque de telares, almacenes de materia prima y producto acabado, laboratorio de calidad, laboratorio de nuevos desarrollos e investigación, así como las oficinas comerciales y administrativas de la empresa.

crecimiento sostenido

El 35% de las inversiones son en equipamientos técnicos para laboratorios propios y proyectos de investigación e inovación.

Empresas de más de 50 países ya confían en nuestros tejidos técnicos.

El crecimiento promedio anual en facturación es del 15%.

El volumen de stocks nos permite entregar más de 10.000 metros de tejido al día.

Nuestro departamento de I+D+I desarrolla una media de 14 nuevos proyectos anuales.

La capacidad productiva actual se sitúa entorno a los 3.000.000 de metros al año.