Trying to summarize the risks of the petrochemical industry is somewhat complicated if we start from the basis that it is perhaps the sector with the greatest diversity of products that can entail risk, deflagrations, explosions, confined spaces, synthesis of various products that can be flammable.

Petrochemical risks:

- ATEX areas

- Reactor

- Storage

- Leaks of gases or flammable products

- Pipelines for combustible materials

- Deterioration, corrosion of deposits that can lead to spills

- Transfers, product handling

- Traffic at the facilities

- Electrical maintenance

We have a high range of risks, from a simple storage of a combustible substance to an explosion in a reactor.

- Areas where high visibility is required EN 20471.

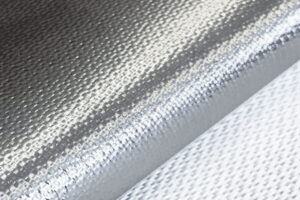

- For the most part, it will be necessary to have an antacid protection EN 13034 or higher depending on the products to be handled. Of course, a fireproof clothing is required whenever the products or operations carried out may have a flame hazard EN11612.

- Electrical maintenance equipment must be protected against arc and must comply with the corresponding standards EN61482-1-1 or EN61482-1-2 depending on the requirements.

- It is vital in these environments have equipment that dissipates electrostatic charges so it must be certified according to EN1149-3-5.

Most of this industry has ATEX Zones (explosive atmospheres) and works in confined areas that can be of high risk if they are not accessed with the corresponding detectors and with assisted breathing equipment. The confined spaces are also areas in which the operator must always be accompanied.

The PPE used by this sector will depend on the risks of each one of them, the products and elements they use. Each company must define the risks and determine the measures that it must put both at the structural level and at each worker.

So far we have only talked about the risks derived from fire and flame, but we must also comment that in this type of industry there are other types of risks that directly affect people’s health can be generated, such as:

- Skin irritations

- Allergic reactions

- Respiratory problems, inhalation of dust, gases, vapors, fumes.

- Ionizing and non-ionizing radiation

- Noise areas that can cause hearing problems

- Exposures to all kinds of substances.

As we can see, it is one of the industries with the highest risk in all areas. Prevention departments have extra work. Emergency plans, evacuation, risk control in different areas and within the same plant, and above all continuous training for all workers, since without them and their involvement in accident prevention models, it is impossible to achieve the best of results.