solutions for welding

Welding is an essential industrial activity carried out in various sectors such as construction, manufacturing, and machinery repair. However, working with welding involves risks such as sparks, UV radiation, extreme heat, and splashes of molten metal. To protect workers from these hazards, it is crucial to have the appropriate protective fabrics. In this blog, we will explore different solutions for welding protection.

Personal protective equipment:

1. Jackets, pants, and coveralls:

These protective garments are designed to cover the torso, arms, and legs of welders. They are made of inherent flame-resistant fibers such as modacrylic combined with cotton, Tencel, and antistatic materials. When choosing the appropriate welding fabric, it is essential to consider durability, comfort, and protection against sparks and splashes of molten metal.

Inherent flame-resistant fabrics intended for welding protection should be certified according to EN ISO 11611 standards, and the choice between class 1 or class 2 should be based on the required level of protection. A debate that can arise in welding protection is the use of leather garments or jeans. While they can be functional solutions, they may have certain disadvantages that affect the comfort and durability of the personal protective equipment (PPE). In this post, we explain each of them.

2. Aprons, sleeves, and leg covers:

An option for workers who are not constantly welding is the use of PPE that can be easily put on and taken off, and only worn during the welding activity. This way, they gain comfort as they can wear lighter fabrics and protect themselves only when necessary. These temporary PPE items are also made of inherent flame-resistant fabrics.

3. Welding gloves:

Welding gloves are essential for protecting hands from burns and injuries caused by sparks. These gloves should be made of heat-resistant materials such as leather and fabrics with flame-retardant properties. It is also crucial for the gloves to provide sufficient dexterity and sensitivity to handle welding materials and tools correctly.

4. Additional protective accessories:

In addition to the aforementioned garments, there are other welding protection accessories that are important for ensuring safety in the workshop. These include helmets with visors to protect the head and eyes, face shields, foot protectors, and fire-resistant safety footwear.

Construction elements:

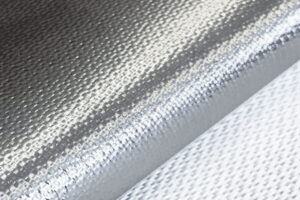

5. Welding blankets and curtains:

In addition to personal protection, it is also important to protect the work environment. Welding blankets and curtains are useful tools for containing sparks and splashes and creating protective barriers around the welding area. These blankets and curtains are made of fire-resistant fabrics, mainly fiberglass, and offer effective protection against heat and UV radiation.

Finally, we present this summary table with some of our solutions for welding work and related techniques, based on their application and level of protection.

| PPE | Jacket and plants | Class 1 | Marko AT320 Marko AT320SW | |||

|---|---|---|---|---|---|---|

| Class 2 | Marko AT400TLP Marlan 460 | |||||

| Sleeves, aprons and leg covers | Class 1 | Preox 300SW Marko AT320SW | ||||

| Class 2 | Marlan 460SX Marko AT400TLP SW | |||||

| Construction Elements | Curtains | M1 | Marglass S590 | |||

| Blankets | M2 | Marglass SX730 | ||||